Up in the cool highlands of Benguet, something hopeful is happening in coffee. During the first ABCD-MAP session of 2026, I shared my own path, from homemaker to artisan coffee producer, and how small-batch, high-quality coffee can create real opportunities for rural communities. This is a snippet from the interview below:

From roots to roasts

My entry into coffee started in 2018 because of my daughter’s persistence, and a discovery that pulled us back to our roots. While managing our family property in Balili, Mankayan, Benguet, I learned my husband’s family had been backyard coffee growers since 1906. I didn’t grow up around coffee farming. When we started, I had never even seen a coffee plant up close.

But I’m a food technologist, so I leaned into what I knew. Learn the science, ask questions, and keep testing. I also used social media and my networks to connect with people who knew the industry. Step by step, the “beginner” stage became a real operating farm.

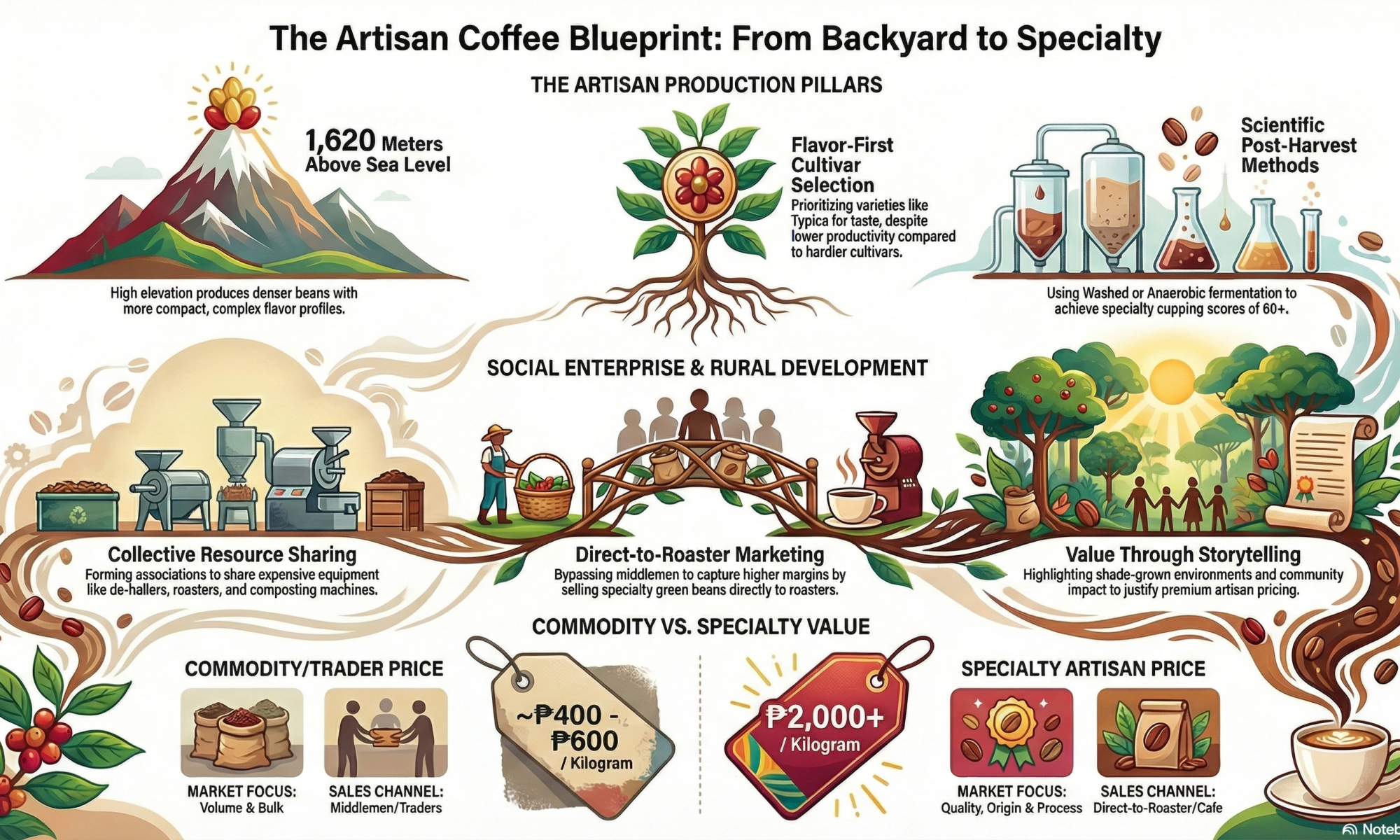

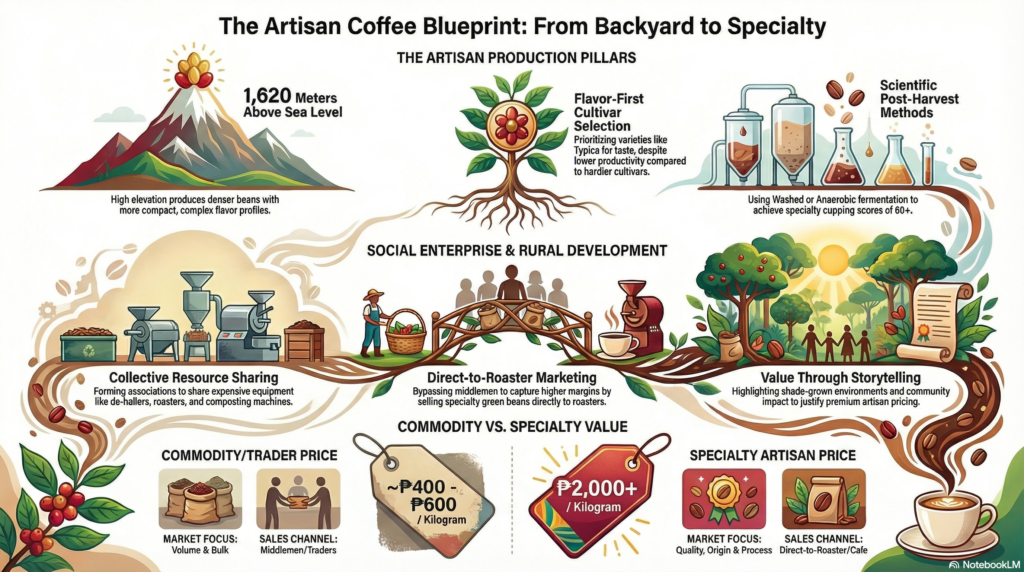

Today, Agnep Heritage Farms is a shade-grown Arabica farm in Balili, Mankayan, Benguet, around 1,620 meters above sea level. We’ve built the farm around a forest-like canopy, including Benguet pine, kalasan, and alnus, because that’s how coffee was grown here long before “specialty” was a word people used.

The science behind how I produce artisan coffee

For me, “artisan” isn’t a marketing label. It’s a constraint and a discipline: small lots, hands-on work, and tight control so I can repeat quality, not just get lucky once.

Early on, I faced problems that forced me to get serious about systems, like mislabeled seedlings and spoilage risks from weather. So I started matching processing decisions to cultivar behavior, and I kept building my quality control habits.

Here’s how that looks in practice:

Washed process tends to work best for our “Reds” like Typica and Red Bourbon, giving a cleaner profile.

Anaerobic process is what I use for cultivars like Catimor and Granica to push fruity character and lift cup performance.

And I don’t guess. I monitor basics like pH and moisture because consistency is what specialty roasters buy, not just a good story.

Why I built this beyond my own farm

I didn’t want Agnep to be a single-farm success story that ends with us. I wanted it to spread, especially the know-how. That’s why we co-founded Kabatangan Coffee Growers, and why I keep sharing what we learn about planting, post-harvest, and quality discipline. Together, we’ve helped plant over 3,000 additional trees with neighboring farmers.

I’m also straightforward about the economic reality. When farmers sell into commodity pathways, they stay trapped in low returns. But when quality and traceability are real, when the processing is disciplined and the lot identity is clear, coffee can move into premium pricing that actually changes household income. That shift is what rural development looks like on the ground: better prices, more skills, more work opportunities, and more reasons for young people to stay.

A model I can actually sustain

My strategy is simple: protect quality, sell where quality is valued, and keep overhead realistic.

A big part of my sales is green beans sold directly to roasters. That keeps costs down compared to going all-in on retail packaging and the admin load that comes with it. I still roast a portion because it keeps the brand visible and keeps the story connected to real buyers and drinkers.

What I’ve learned is this: small farms don’t win by trying to out-volume anyone. We win by being specific, about place, process, cultivar, and cup profile, and by building systems we can repeat.

That’s the blueprint I’m betting on: clarity of origin, disciplined processing, and shared capability across the community. Even small players can compete when they can produce a profile they can repeat, and a story they can truly stand behind.